The project

The thermal power plant Šoštanj generates 30 % of all energy of Slovenia and is located relatively centrally in the north of the country. The power plant consists of several coal-fired power plant blocks which should be replaced and ecologically optimized by the construction of a new block. The aim is to reduce CO₂ emissions by 35 % using the latest technology as well as reducing SO₂ emissions to a quarter and NOₓ to one third of the previous values. Furthermore, dust and noise limits should be greatly reduced.

The task

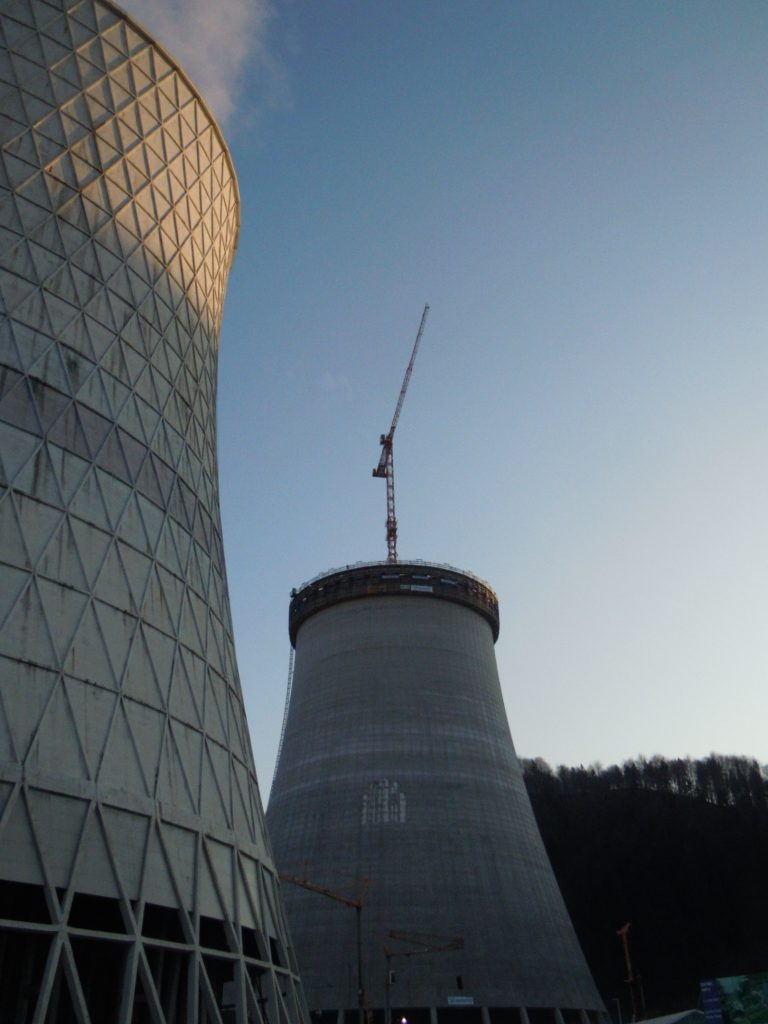

The cooling tower, in which our special version of a WT 300 e.tronic crane was involved, was to be 164.5 m high. The particular challenge with cooling towers is the protection of the tower, which is usually solved by strand stays, and the disassembly of the boom at the end of the project.

The implementation

The WT 300 e.tronic crane was mounted on a foundation anchor in the center of the intended tower. While the tower grew in the slidform process, the tower was climbed three times to a final hook height of 175.5 m. The radius of 60 m generously overhung the base of the tower. The tower was secured by strand stays at 91 and 136 m above ground. At the end of the project, the boom was dismantled mid-air with our boom disassembly mechanism.

The thermal power plant Šoštanj generates 30 % of all energy of Slovenia and is located relatively centrally in the north of the country. The power plant consists of several coal-fired power plant blocks which should be replaced and ecologically optimized by the construction of a new block. The aim is to reduce CO₂ emissions by 35 % using the latest technology as well as reducing SO₂ emissions to a quarter and NOₓ to one third of the previous values. Furthermore, dust and noise limits should be greatly reduced.

The task

The cooling tower, in which our special version of a WT 300 e.tronic crane was involved, was to be 164.5 m high. The particular challenge with cooling towers is the protection of the tower, which is usually solved by strand stays, and the disassembly of the boom at the end of the project.

The implementation

The WT 300 e.tronic crane was mounted on a foundation anchor in the center of the intended tower. While the tower grew in the slidform process, the tower was climbed three times to a final hook height of 175.5 m. The radius of 60 m generously overhung the base of the tower. The tower was secured by strand stays at 91 and 136 m above ground. At the end of the project, the boom was dismantled mid-air with our boom disassembly mechanism.